Jump to: Options - Specifications - Support

XP Drive

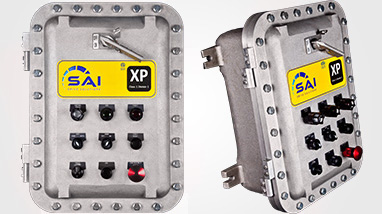

The XP Drive by SAI is an ETL-listed, explosion-proof, packaged VFD designed for use in Class I & Class II Division 1 hazardous locations. The XP Drive includes an industrial variable frequency drive packaged in a compact cast aluminum, NEMA Type 7 / 4X enclosure. The XP Drive includes a mains breaker disconnect, operators, pilot lights and E-Stop.

Development

The XP Drive drive was developed in response to market demand. Prior to the XP Drive the established option to use a VFD within a hazardous atmosphere was a very large and expensive Type 7 enclosure that required purged-air and active cooling. This would usually be cost-prohibitive so the decision would be taken to move the VFD outside the classified area. This solution introduced it's own technical challenges of motor harmonics caused by the long motor-lead lengths.

XP Drive Benefits

The XP Drive in contrast is a cost-effective solution - it's compact, comparatively light-weight, passively-cooled XP VFD. The XP VFD can be installed near the motor avoiding harmonic issues. Instrument-air is not required and there are no active fans to clog or clean. In addition to the lower product cost and reduced installation cost, the XP Drive improves operator safety and process efficiency by offering direct access to VFD controls.

Features

Explosion-Proof

The XP Drive is certified by ETL to conform to UL 1203 and CSA C22.2 standards which approves the equipment for use within hazardous locations (HazLoc). The XP Drive is rated Class I Division 1 (CID1) and Class I Division 2 (CID2) 'Explosion-Proof And Dust-Ignition-Proof Electrical Equipment'.

Classified areas are typically associated with oil and gas industries but are also common in pharmaceutical and chemical processing or any operation where flammable gases or materials are present.

Enclosure

The XP Drive is built using a NEMA Type 7 / 4X enclosure. Type 7 enclosures are intrinsically safe, meaning they are designed to contain an internal explosion preventing a cascading event. The Type 4X rating relates to water and corrosion resistance. The compact enclosure along with hazloc rating enables the drive to be installed near the application / motor.

Passively-Cooled VFD

The XP Drive is designed to cool the VFD during operation by using the enclosure as a heat-sink. The thermals developed by the VFD is transferred into the enclosure and then dissipated into the environment.

By passive cooling the VFD, no air conditioners are required to keep the drive cool and no active fans or their filters which require regular maintenance. This reduces operational management, service costs and enables greater flexibility with installation location.

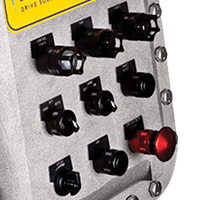

Operators

The XP Drive comes as standard with the following operators and indicators

- Circuit breaker disconnect

- HAND-OFF-AUTO selector switch

- Hand 'OFF-ON' selector switch

- Speed potentiometer

- Fault-reset push button

- Safe Torque Off (STO) CAT 2 Emergency Stop (E-Stop)

- Run lamp

- Fault lamp

VFD Features

The VFD is a world-class compact current vector drive delivering high performance, high functionality and high quality. For a full list of VFD features, download the VFD datasheet below in the support > downloads section.

Communications

Terminal points are included for remote run command & speed reference. VFD supports Fieldbus communication option cards for alternative protocols and contactors. See options for more details.

Options

Digital Display

The XP Drive can be fitted with an digital display to show real-time VFD parameters. The display can be configured with either one or two meters. The display window is added by mounting an XP Type 4X window enclosure to the top of the XP Drive with unistrut.

The meters can be set to display motor RPM, Hz or Amps. The values are fixed based on configuration. The units can be changed by connecting a USB to the meter(s) and changing the configuration settings through vendor supplied software.

Front Cover Power Coating

The front cover of the enclosure can be painted to reduce the surface pitting and improve cleaning and aesthetics. For more information about color options contact sales for color guides.

45°C or 50°C Temp Rating

The XP Drive by default is rated for 40°C however as an option the drive can be configured for 50°C or 55°C temp rating.

Transient Surge Protection

Transient surges such as those caused by lightning or current inrush from a transformer can cause damage to solid state devices which are present in the VFD. For improved electrical protection, the XP Drive can include a Raycap surge protection device (SPD). Learn more about Raycap SPD devices Transient Surge Protection - Raycap SPD

Input or output line reactor

A 3% line reactor can be add to the XP Drive on either the input or output side. This device reduced harmonics produced by the VFD and can help minimize total harmonic distortion (THD)

Configurable XP Operators and XP Pilots

The XP Drive is offered with a standard set of operators and pilots. The configuration of which can be modified as part of a custom build request. Additional operators can be added or operators removed. Examples of alternative operators include combined start / stop push-buttons, padlock device, push / pull switch, key-lock selector switch and different color pilot lamps.

Custom NPT locations and sizing

To support custom wiring additional NPT holes can be added to the top and bottom of the enclosure. The standard NPT size can also be adjusted.

Communications

By default the VFD supports ModBus RTU via RS 485. Alternative FieldBus protocols are available through I/O cards. Protocols supported include:

- Profibus

- Profinet

- DeviceNet

- Ethernet/IP

- ModBus

- TCP/IP Mechatrolink-II

Applicable Markets & Industries

Oil extraction / artificial lifts, petroleum refineries, petrochemical, gasoline storage and dispensing areas, pharmaceutical, chemical, distilleries, dry cleaning plants where vapors from cleaning fluids can be present.

Paint booths (spray paint, finishing areas), aircraft hangars and fuel servicing areas, utility gas plants and operations involving storage and handling of liquefied petroleum gas or natural gas.

Water and wastewater facilities, producers of plastics, medicines and fireworks. Producers of starch or candies, spice-grinding plants, sugar plants and cocoa plants

Specifications

Power

200-240 VAC 1-Ph, 1/8 to 3 HP (HD)

200-240 VAC 3-Ph, 1/4 to 10 HP (HD)

380-480 VAC 3-Ph, 1/4 to 20 HP (HD) & 25 HP (ND)

* HD refers to heavy duty / constant torque. ND refers to normal duty / variable torque.

** 120VAC 1-Ph input voltage can be supported in a CID2 environment by using an aftermarket CID2 120:240VAC step-up transformer.

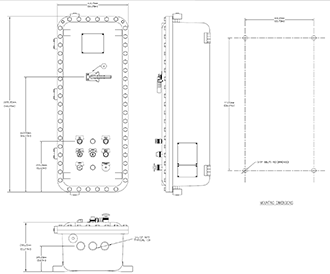

Enclosure

NEMA Type 7 / 4X Cast Aluminum Alloy

HazLoc Rating:

Class I Groups B, C & D

Class II Groups E, F & G

Class III. Type 4

| Enclosure Size Lookup Table | |||

| The following table lists the XP Drive enclosure size by HP for a given input voltage and phase. The enclosure selection is based on a standard XP Drive build with a temp rating of 40C. | |||

| HP (HD) | 208-240 VAC 1-Ph @ 40C | 208-240 VAC 3-Ph @ 40C | 380-480 VAC 3-Ph @ 40C |

| 1/8 | B8 | ||

| 1/4 | B8 | B8 | B8 |

| 1/2 | B8 | B8 | B8 |

| 3/4 | B8 | B8 | B8 |

| 1 | B8 | B8 | B8 |

| 2 | B8 | B8 | B8 |

| 3 | C8 | B8 | B8 |

| 5 | B8 | B8 | |

| 7.5 | D8 | C8 | |

| 10 | D8 | C8 | |

| 15 | D8 | ||

| 20 | D8 | ||

| 25 (ND) | D8 | ||

| Frame | Dimensions | ||

| B8 |

XCE 22.25 x 16.25 x 10.89

|

||

| C8 |

XCE 28.25 x 16.25 x 10.89

|

||

| D8 |

XCE 40.25 x 16.25 x 11.27

|

||

Operating Temperature

The operating temperature is -10C to 40°C as standard with optional 50°C & 55°C rating available.

Certification

The XP Drive has been independently tested by ETL (Intertek) confirming it complies with regulations and safety standards for use within hazardous location (hazloc) environments. As part of the right to ETL-Mark, the products the XP Drives are subject to ongoing quarterly production inspections.

The XP Drive is approved for use in hazardous atmospheres:

Class I, Division 1, Groups B, C, D

Class II, Division 1, Groups E, F, G

Temperature code: T5 (100°C)

Ambient Temperature: -10°C to +50°C

"The XP Drive is certified as an explosion-proof & dust-ignition-proof electrical equipment product for use within Class I & II; Division 1 classified areas."

Electrical Equipment for Use in Hazardous (Classified) Locations

- UL 508A Issued: 2013/12/20 Ed: 2 Rev: 2014/01/13 Industrial Control Panels

- UL 508C Issue:2002/05/03 Ed:3 Rev:2010/11/09 Power Conversion Equipment

- UL 1203 Issued: 2013/11/22 Ed: 5 Rev: 2015/04/24 Explosion-Proof & Dust-Ignition-Proof

- CSA C22.2#14 Issued: 2013/03/01 Ed: 12 Industrial Control Equipment

- CSA C22.2#30 Issued: 1986/11/01 (R2012) Explosion-Proof Enclosures for Use in Class I Hazardous Locations General Instruction No. 1, 1986, General Instruction No. 2, 1988

- CSA C22.2#25 Issued: 1966/09/01 (R2014) Enclosures for Use in Class II Groups E, F, and G Hazardous Locations; Gen. Inst. No. 1: 1966

XP Drive, ETL-Listed (Intertek) Marking - SAI File 5004518

FAQ's

What is the standard lead time for an XP Drive?

- Lead times are from receipt of purchase order and signed approval drawings

- Lead time for a standard XP Drive build is 1 - 2 weeks

- Lead time for custom build is 2 -3 weeks

Where do I find the VFD serial number?

The XP Drive specification plate is on the right-hand side. The serial number will be displayed in the table on the top right of the plate and will have the following format "YYYYMMDDSSS" i.e. 20210320001.

How do you make changes to the VFD parameters / programming?

To configure the VFD you will need to move the drive outside the rated area. The enclosure will need to opened so you can connect a communication cable to the VFD. VFD software is supplied upon request. Once connected, make the appropriate changes through the software.

Downloads

For product related downloads including brochures & manuals visit the support resources section by clicking on the link below.

Contact Support

For technical support email support@saidrives.com or call 281.516.3130.